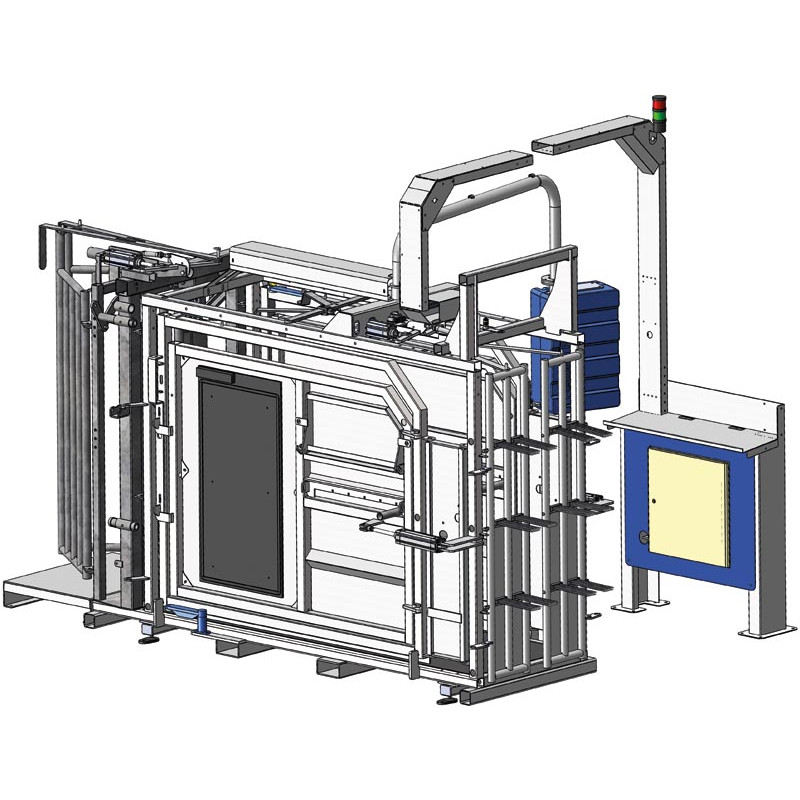

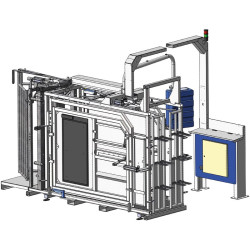

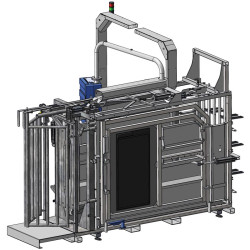

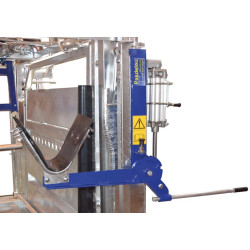

LVAPI crush - Sheeted panels - Adjustable sides - Opening sheeted side panels

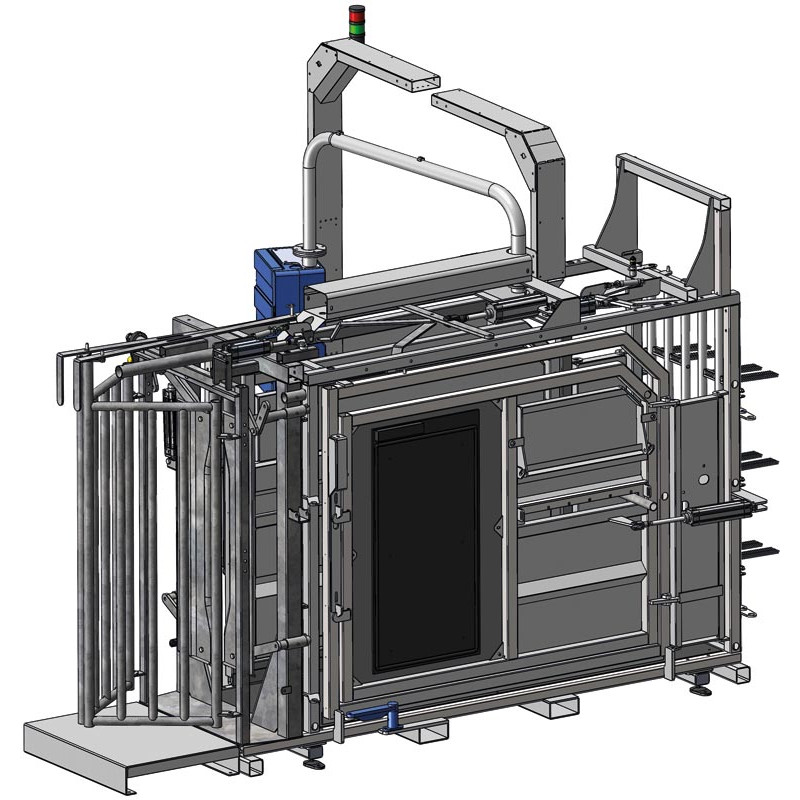

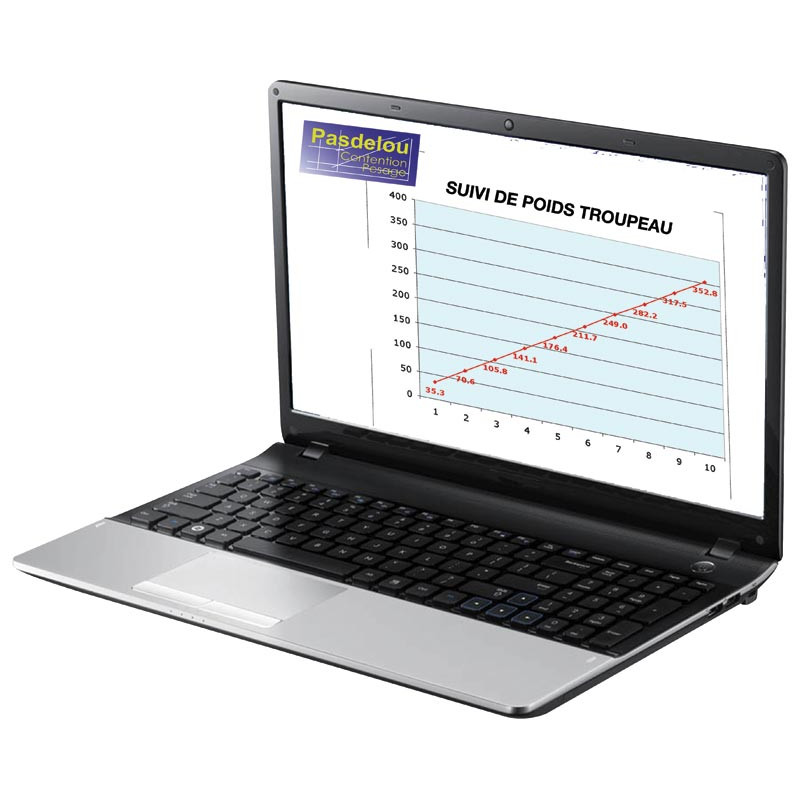

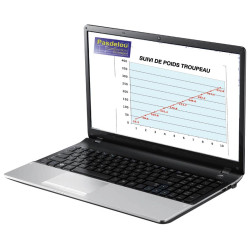

Drafting is fully automated using the PLC linked to the weighing data and its EID panel.

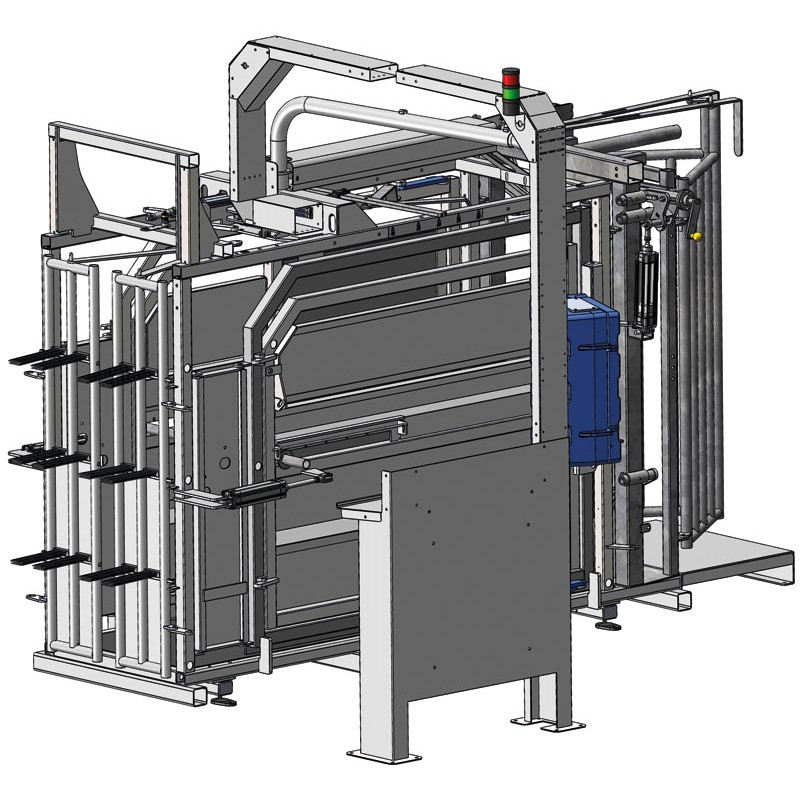

- Galvanised steel crush equipped with a ⧄ 60 mm reinforced frame,

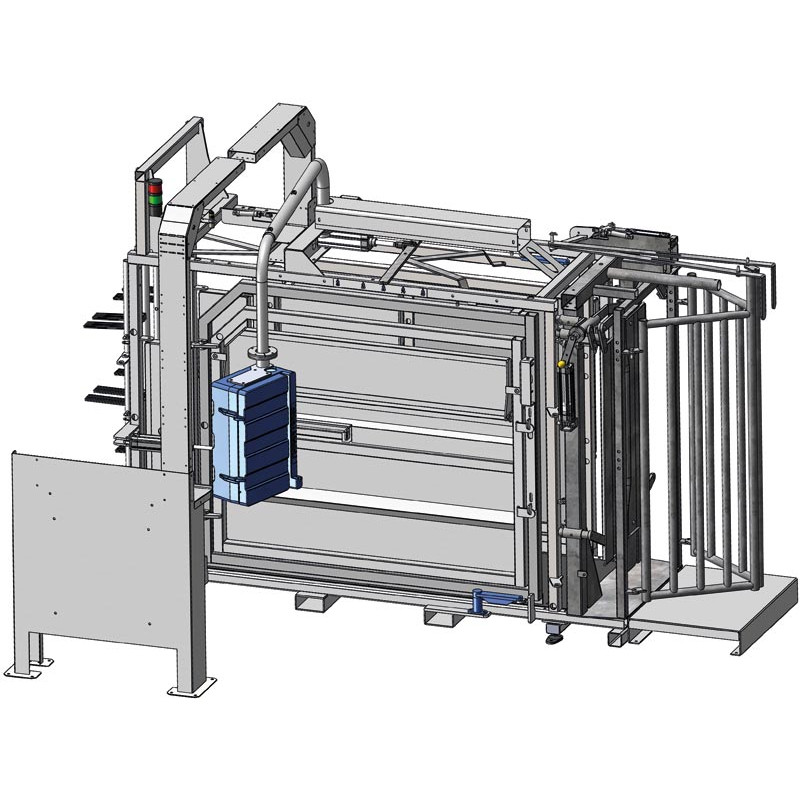

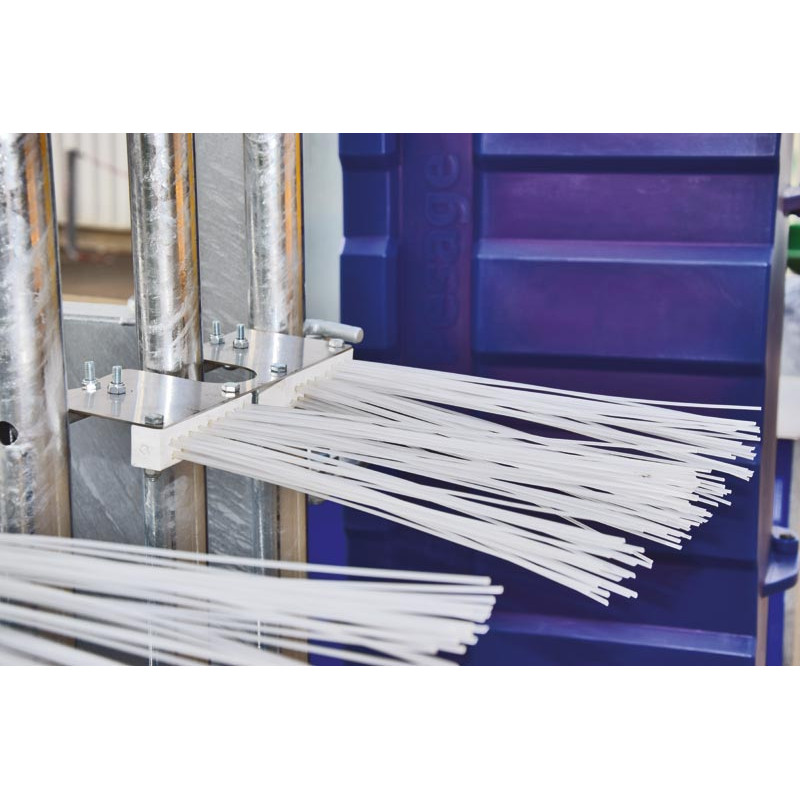

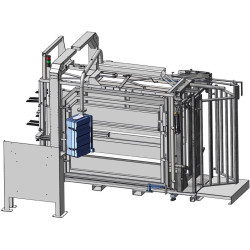

- Pneumatic rear gate with 2 leaves. Pneumatic control. Leaves equipped with retractable, vibrating and sharp filaments. Patented system which creates free space between the crush and the animals behind, to prevent a distorted weight reading during weighing,

- Factory-fitted non-slip mat on the bottom to prevent slipping and to limit noise,

- Passage sous la cage prévu pour son déplacement lors de l’installation par les fourches d’un chargeur avant,

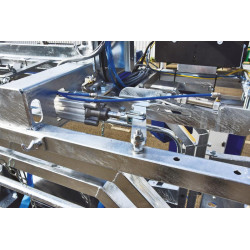

- Reinforced rotating connection rods welded to a mechanical tube with grease nipples,

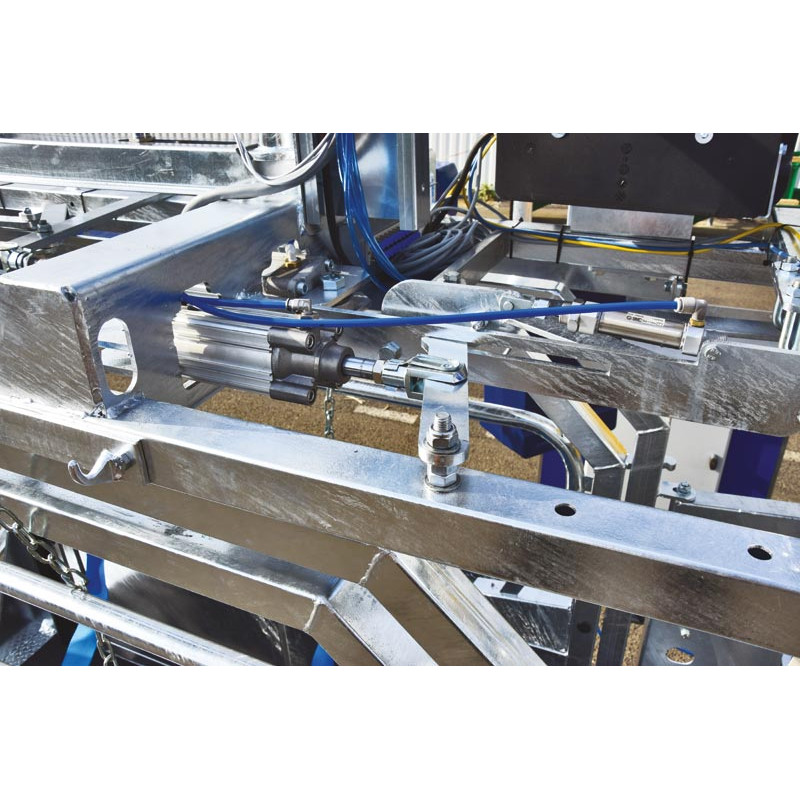

- Pneumatic cylinders operating on a pressure of 5 bar. The diameter of the cylinders depends on the force to be applied to open each component. Each of the components that are operated by the cylinders are equipped with a mechanical safety device with a hard stop to limit cylinder stress and breakage, especially when pushed by the animals,

- Factory-fitted cattle crush exit threshold,

- Factory-fitted PCCM AP pneumatic gate,

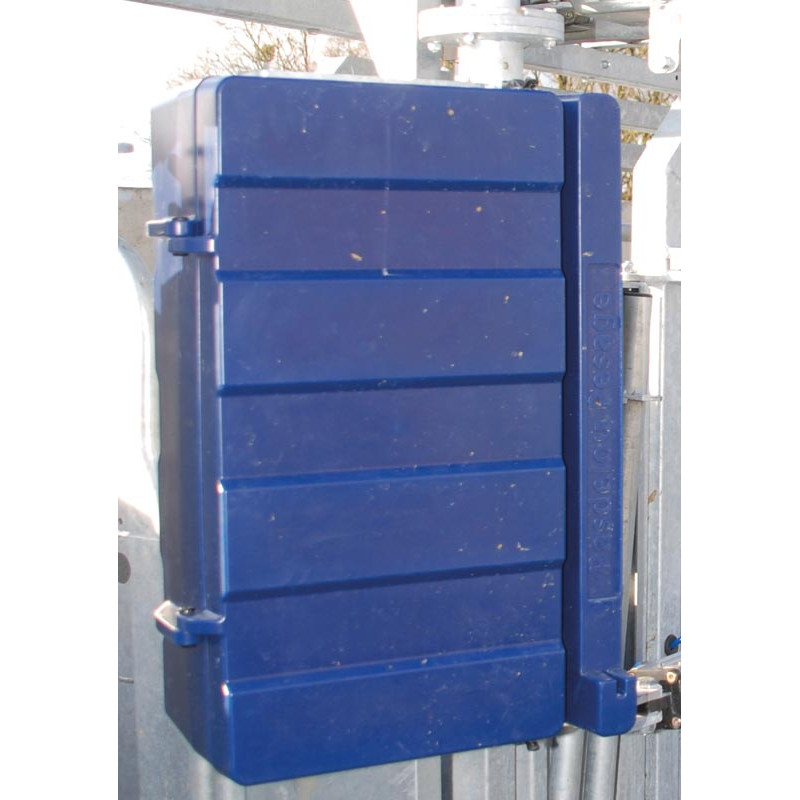

- Waterproof polyethylene cabinet with padlock ring and latch attached to a removable and reversible arm. Equipped with a P05 weighing unit and pneumatic cylinder control unit,

- Front side panel with EID tag reader,

-& Control panel on support frame.

Technical, electronic and pneumatic parts installed with this crush:

A P05 weighing system pack comprises:

- 1 P05 weigh scale indicator (Operation and data collection, draft management, connectivity)

- 1 x 12 V battery power cable,

- 2 load bars (length 0.94 x width 0.15 x height 0.11 m)

- 2 sensor cables, length 10 m for connection to the weigh scale indicator.

A control box equipped with:

- a keyboard with touchscreen control,

- an electric and pneumatic emergency stop,

- 2 pneumatic and electrical power-on LED indicators.

PLC control of the crush with its gates plus 2 additional stop gates in a fixed crush.

A watertight, electrical and pneumatic lockable cabinet equipped with:

- Solenoid valves operating at 12 V,

- 2 x 220 V sockets for connecting power tools,

- 1 x 220 V to 12 V transformer,

- 1 pneumatic pressure regulator with safety valves,

- flow regulators enabling the flow rate, and therefore the operating speed of each pneumatic cylinder, to be adjusted position by position,

- 1 document holder shelf.

This cabinet is mounted on a galvanised frame, which must be fixed to the ground and then connected to the crush by a fixed extension arm to route the cables.

The electrical connection system is in accordance with the standards in force for machine tools.

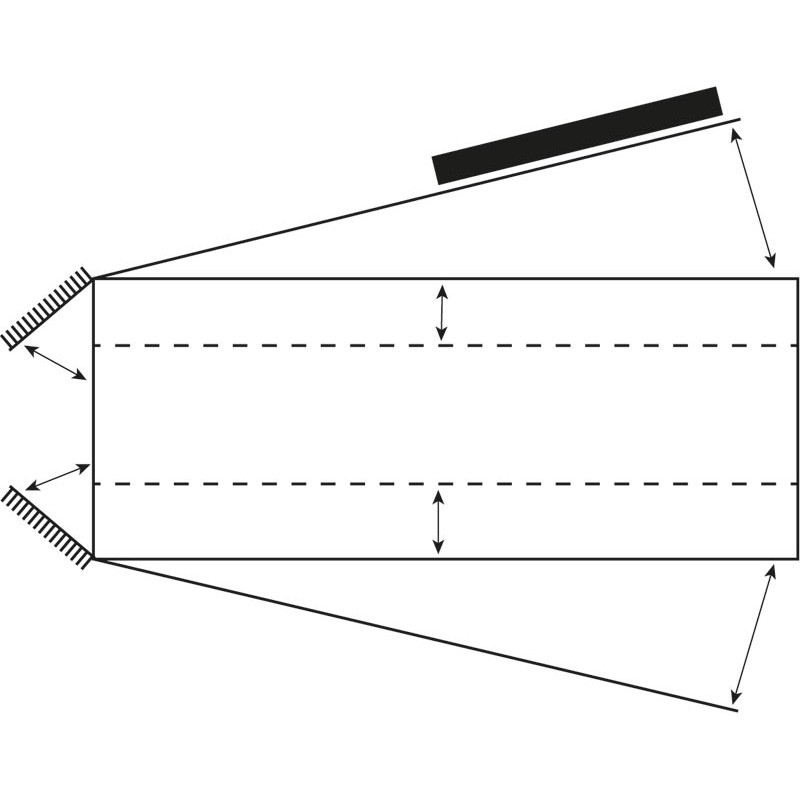

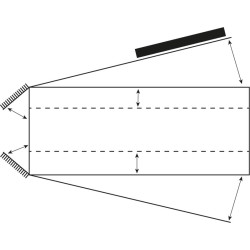

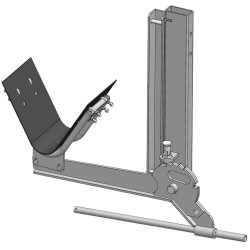

- Opening side panels with adjustable width for side draft,

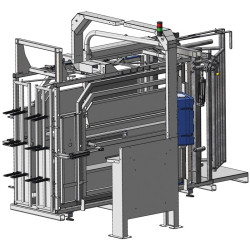

- Sheeted fixed panels on lower part,

- Sheeted leaves, removable and retractable at the top,

- Anti-backing system with blocking by a large bar.

Starting up and training after installation by our team of professionals at PASDELOU.

- Height

- 3.05 m

- Length

- 4 m

- Width

- 2.86 m

- Sales unit

- Unit

- Packaging

- Without packaging

- Operation

- Pneumatic crush with smart technology

- Sides

- Adjustable width

- Inside width

- adjustable from 0.40 to 0.80 m

- Inside length

- 2.70 m

- Side panels

- Sheeted openings and EID reader

- Side openings

- 2 opening panels, 1 EID reader panel and 2 removable and retractable leaves, sheeted at the top

- Floor

- Rubber mat

- Drafting

- 3-way

- Access to the animal

- Top part

- Purpose

- Drafting/Weighing/Care

- Type of animal

- Beef cattle

- Installation

- Fixed crush

Accessories and options